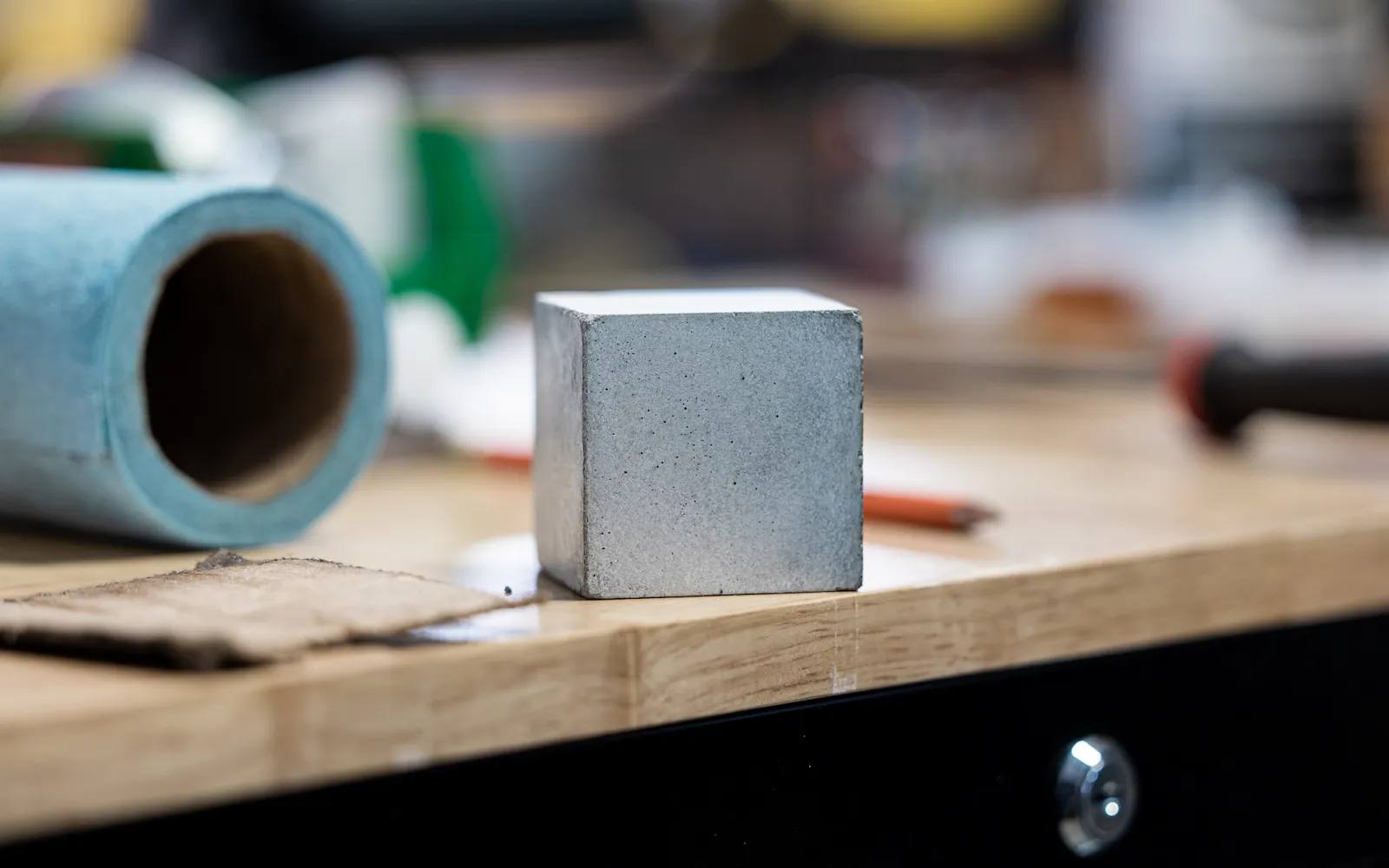

Ordinary portland cement (OPC), the binder in most forms of concrete, is made by heating limestone (calcium carbonate), a process that releases huge amounts of CO2—about 8 percent of the world’s annual total. To meet climate goals without crippling the global construction industry, nations need a zero-carbon or carbon-negative ways to make cement. Brimstone makes OPC by feeding calcium-silicate rocks such as basalt, rather than limestone, into its kilns. The process produces calcium oxide — the key ingredient in cement — without releasing carbon, and if Brimstone’s kilns are heated with renewable energy, the overall process is carbon-negative.

News & Insights

In a deep-tech twofer, Brimstone aims to secure U.S. aluminum supply

Brimstone's $189 million federal award is a game-changer for cement decarbonization

DCVC 2023 Q2 update

Brimstone receives ASTM certification for its OPC: can now replace 98% of world’s cement

Brimstone: Rock Stars of the Cement Industry

DCVC 2023 Q1 update

DCVC Welcomes 2022

Reinventing Cement for a Zero-Carbon Future

In The Media

Clean cement startup Brimstone can make another key material: alumina

Start-ups Trying to (Profitably) Solve the World’s Hardest Problems

Current Climate: Limiting ‘Forever Chemicals’ In Drinking Water

Energy Department awards $6 billion for green industry buildout

6 innovative startups that are kicking CO2 out of cement and concrete

The Best Inventions of 2023

To decarbonize cement, the industry needs a full transformation

This startup CEO claims he can completely decarbonize the cement industry

Green linings & lessons from breakthroughs #159

Cement warms the planet. This green version just got a key nod of approval.

Cement is responsible for 8% of global emissions—but it doesn’t have to be

The Funded: UserTesting raises $140M in downsized IPO that missed its targets

The good times keep rolling for small, e-commerce business owners

Changing up the recipe to make low-carbon cement

Explore Companies

Alta Resource Technologies

Using advanced biochemistry to create a secure supply of critical minerals from waste and other low-grade sources

Slip Robotics

Automating loading dock operations

Recycleye

Reinventing the economics of recycling

Cato Digital

Making hyperscale computing cleaner and more efficient through power management