We’re excited by Zymergen’s latest funding of $130 million to aggressively scale its machine learning and applied robotics platform. This platform enables precision engineering biology at industrial scale and quality, optimizing existing products and producing breakthrough new ones in agriculture, life-sciences, and manufacturing. It was an easy decision for us to continue to invest in Zymergen, which we’ve backed since its seed. Their technology lead is huge and self-reinforcing, and they have an impressive number of global Fortune 500 customers, outstanding financial metrics, and a world-class team.

We’re pleased that this success attracted the support of SoftBank, which brings Deep Nishar to join us on the Zymergen Board. Both SoftBank as a company and Deep as a person have track records of driving category-killer results. Deep was a senior executive at both Google, where he drove their international strategy, and LinkedIn, where he led all product, for many years.

We’re also honored to welcome former U.S. Secretary of Energy and Nobel Laureate Dr. Steven Chu as an independent director on the Zymergen Board.

Materials science has brought incredible discoveries in the 20th century, from the aluminum alloys that make cars lighter and safer, to the carbon fibers in everything from tennis rackets and Boeing 787 jets, to the speciality materials that make every digital display screen possible. But we know that nature is more inventive than we are. The microorganisms in a single cubic meter of soil carry out more — and more complex — chemistry experiments in a day than every human scientist on Earth in their lifetimes.

We’ve adapted nature’s ingenuity, selecting strains of microbes that turn their food (some organic material, from grape juice to woodpulp) into chemicals of use to humans. Conducted at scale, and in vessels from barrels to giant steel vats, this process is called industrial fermentation. Without fermentation, we wouldn’t have beer and wine to drink, cheese and chocolate to indulge in, and insulin, vaccines and antibiotics that help keep us healthy. Many of the discoveries were made due to observing nature, which is a relatively slow process of trial and error.

Even in labs, the field of biology has long relied on extremely labor-intensive and time-consuming experiments. Until only very recently, biologists were reduced to crossbreeding yeast, like medieval brewers, to learn more about key genetic traits. However, in the last thirty years, a revolution in the ease, accuracy, and cost of genetic sequencing has produced a wealth of information about microbial genomes. Coupled with a parallel revolution in techniques for precisely altering those genomes, it is now possible to conduct biology experiments with vastly more precise understanding of initial conditions and expected outcomes. This twin revolution moves us closer to making biology more like engineering.

To date, scientists have classified about 200,000 naturally-occurring chemicals — millions more are likely to exist.

Zymergen

Engineering biology doesn’t mean simplicity, but it does mean repeatability and precision in a data-driven self-optimizing feedback loop. Today, the semiconductor industry’s path from an idea to functional chip requires the following:

The semiconductor industry also benefits from the ability to rapidly test ideas. Many variations of potential chip designs are placed on a single silicon wafer in a so-called “shuttle run,” where one or a few wafers are experimental candidates in an otherwise production manufacturing process. Conversely, proven designs can be run relatively quickly in an unproven manufacturing process to learn what to fix about a new process.

The semiconductor industry learns from its tests, both of individual chip designs and of overall manufacturing process itself, and collects tremendous amounts of fine-grained data. The industry then uses these huge pools of proprietary data to rapidly iterate improvements to both individual chip designs and manufacturing process, as well as the design software that drove the chip designs to begin with. This is the data-driven self-optimizing feedback loop that has supported much of the pace of Moore’s Law for almost 50 years.

The companies that mastered this “deep stack” (as DCVC calls it) of high-complexity software running on high-performance compute, cutting-edge hardware, and industry specific knowhow in the semiconductor business became multi-decade sustainable giants, like Intel, ARM, Qualcomm, and TSMC.

We believe that Zymergen’s breakthrough is in its own “deep stack” that enables engineering biology akin to the semiconductor industry’s process.

First, precise design: Zymergen’s AI-powered genome design software explores a search space orders of magnitude more complex than Google’s DeepMind AlphaGo. This search is to find exactly the genome of exactly the right organism that will produce the desired results. These include the material produced (e.g, ballistic nylon versus hypoallergenic adhesive), the energy efficiency/productivity (which correlates to profit margins), byproducts produced or lack thereof (better), and even subtle tweaks like inter-organism stickiness (less viscosity means less energy to stir a fermentation tank).

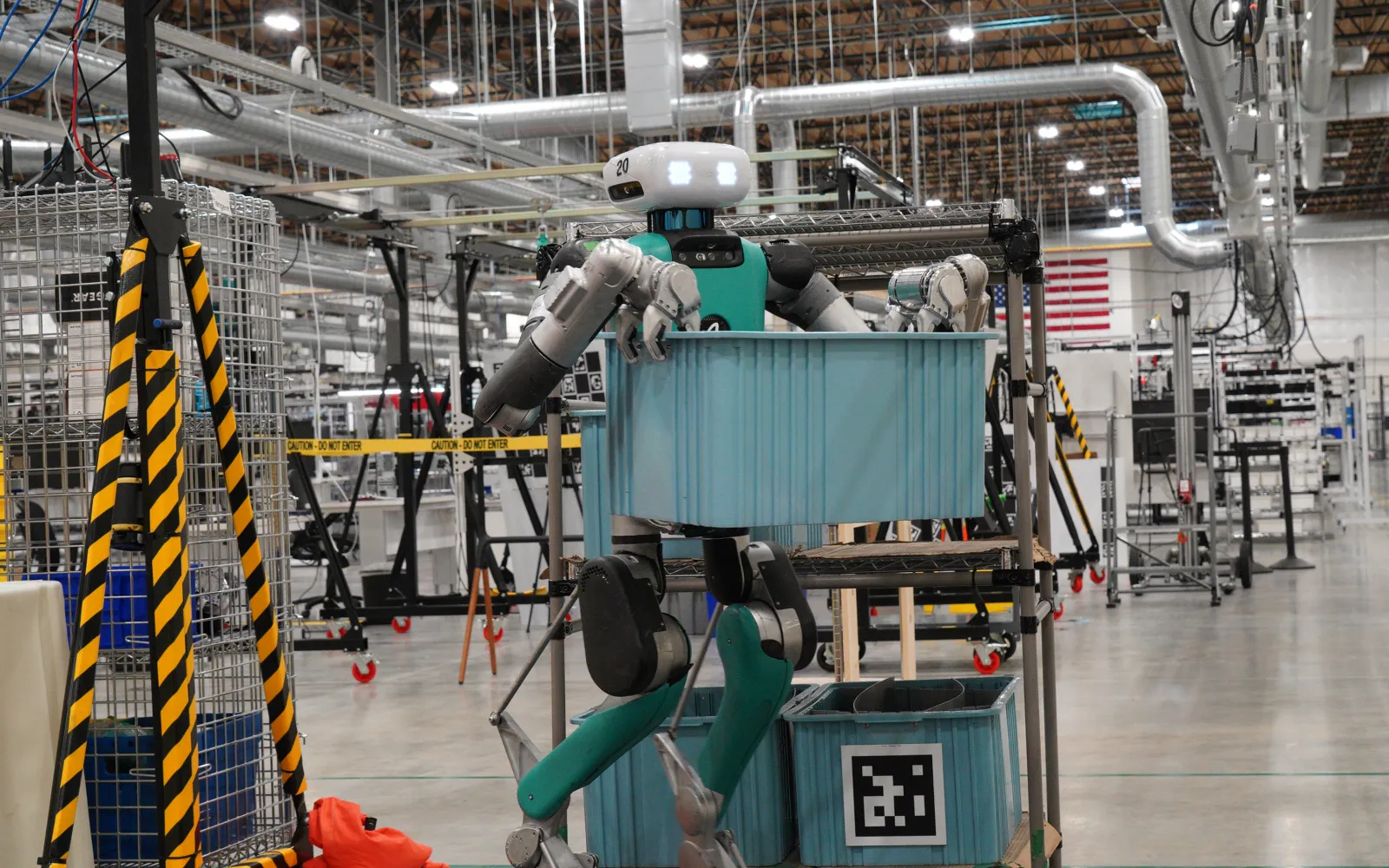

Second, repeatable and precise manufacturing: in 2015 alone, Zymergen’s automation systems supported tens of millions of discrete operations in 2015 alone — the equivalent of roughly 10,000 scientists advancing a delicate experiment one step every hour, 24×7, for a year, reproducibly and at extremely low error rates. Almost every operation at Zymergen to engineer and test an organism is automated and de-risked from human error: robots pipetting, macro and micro-fluidic flows under precise computer control, flasks heated and cooled and shaken with tireless machine fidelity.

Third, obsessive instrumentation: every single step of Zymergen’s manufacturing and testing process is heavily instrumented, collecting fine-grained data in real time. This data is fed into manufacturing machine learning systems that self-optimize to avoid errors and work better, faster, with less energy and fewer steps — saving material amounts of time and money. This data is also fed into Zymergen’s core AI organism design platform.

It is important to note that Zymergen is optimizing its platforms and manufacturing across multiple organisms at the same time. Typically, industry uses a few types of bacteria such as S. cerevisiae (yeast) and E. coli (bacteria), but Zymergen is able to use other microbe models in addition to adding fungi, gram-positive and gram-negative bacteria as potential hosts.

The result is a true data-driven self-optimizing feedback loop that improves the cost, speed, quality, and reliability of Zymergen’s design software, manufacturing processes, and final engineered biology outcomes. With every single customer and every single process step for every customer, Zymergen has built and continues to build a sustainable, self-reinforcing advantage. This kind of lead is extremely hard to surpass, even with lots of money and time, because Zymergen’s advantage improves geometrically over time, leaving any competitor starting from today or even a while back at a permanent disadvantage.

Zymergen has created a systematic approach to engineering biology, using AI, robotic and machine-learning driven manufacturing, hyper-scale big data, and massively scale out compute. Fortune 500 companies now rely on Zymergen to deliver microbes that ensure that industrial-scale, high-value products are manufactured in a repeatable, precise, high quality, and low-error rate process.

Investing from the Beginning, Helping Throughout

We knew of Zymergen’s initial work because a co-investor in some of our other deep tech companies had been the graduate thesis advisor to Zymergen’s CTO. An angel investor introduced us to Josh Hoffman, the CEO of Zymergen, about the same time, several years ago.

When the DCVC team heard the Zymergen pitch, we knew our investment thesis that deep stack leaders (especially those with ground-breaking AI advantages) transform industries matched Zymergen’s approach to engineering biology. We have invested twice since our seed investment, in fact leading the round prior to Softbank’s, because we believe the company transforms many pivotal biology problems into solvable engineering problems with multi-billion-dollar outcomes. The founding team came to us with a vision to unite genomics, robotics, hyper-scale data, massive compute, and artificial intelligence to improve the industrial production of materials, and they continue to execute on that vision.

DCVC is pleased that we were able to contribute materially to Zymergen’s current and ongoing success. From day one, we were involved in technology strategy, helping analyze and decide on software and systems implementations, providing expert knowledge from our Equity Partners (our network of world-class technologists, scientists, and entrepreneurs who share in common in our firm’s results) and key introductions from across our portfolio of other cutting edge companies.

We played a hands-on role in recruiting key employees, delivered critical Fortune 500 customers from initial introduction through making sure they signed contracts, advised on important intellectual property and patent issues based on decades of experience, and offered management unyielding support and a sounding board while still delivering frank and constructive advice. At elite gatherings of both research and industry leaders we host, we made sure Zymergen had a chance to recruit talent, make alliances, and pitch customers.

When Zymergen needed substantial financing to capitalize on its early progress, but didn’t want to take months to persuade outside investors, we stepped up to lead the key “inflection” financing. And, DCVC played an essential and active role in assembling the participants for and then closing this current round of funding.

Even in the most well-studied organisms, we only know what two-thirds of the genetic sequence does because the annotation remains incomplete

Zymergen

At one of our annual DCVC events, Josh described how Zymergen’s technology would impact drug delivery. The coatings on drugs are not capable of releasing a steady dose throughout the day. What if you could create a peptide enclosure for drugs that could precisely release therapeutics all day long?

What if you could create surgical glue that was both hypoallergenic and antimicrobial? Or bandages that healed as they were absorbed harmlessly into the skin? What if you could create polymers for flexible optical electronics? The possibilities for truly novel microbial-derived products are endless and inspiring.

But the problem space seems daunting.

Today, these innovations seem beyond reach because of the informational complexity of the microbial genome, and the time to test hypotheses about how to put it to use. However, Zymergen’s ability to iteratively search, engineer, and test organisms at orders of magnitude greater speed than has existed to date is already delivering breakthroughs.

We can’t talk about these breakthroughs yet, but if you don’t read about them here, you probably will in a major news outlet soon enough.