Fulfil

Automating online grocery fulfillment to lower costs

A third of all the food produced on the planet is lost or wasted each year, according to the United Nations. In a world where 10 percent of the population regularly goes to bed hungry, this is a humanitarian failure. It’s also an environmental one, because the carbon emissions associated with food waste are nearly equal to that of all road transportation, combined.

On September 29, the UN is holding a Day of Awareness to call attention to the problem of food waste and potential solutions. One area of the economy facing scrutiny is the retail sector, which in high-income countries is estimated to account for 13 percent of all food waste.

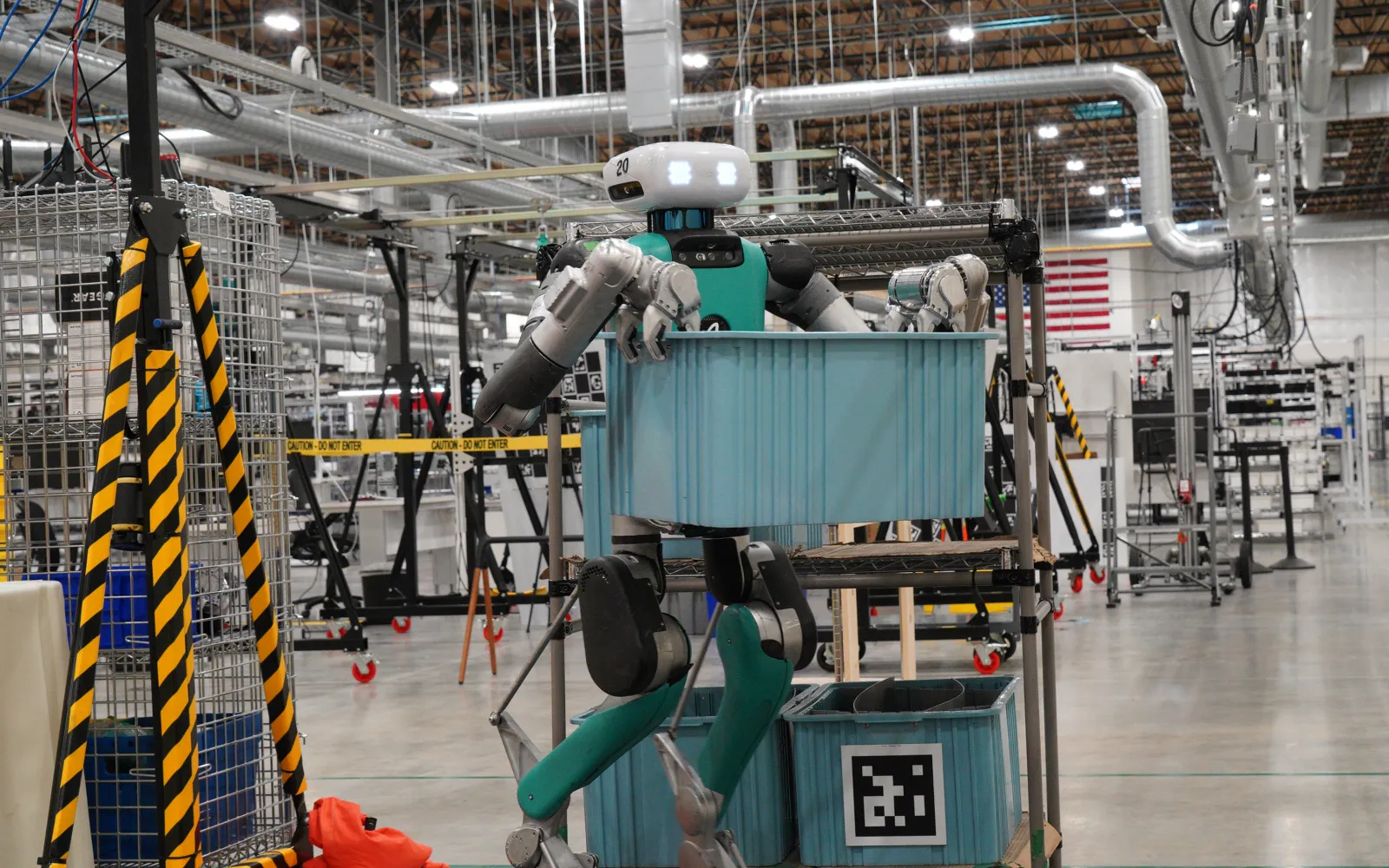

DCVC portfolio company Fulfil Solutions, which has deployed a completely unique, fully automated fulfillment system to enable customer-centric, profitable online grocery at scale, is among those working to address the problem. Fulfil’s automated platform is distinguished not only by R2D2-like robots that pick and pack groceries across all product categories and temperature states, but also by advanced inventory-control software that tracks every item individually. (See answer to last question for current state of Fulfil deployment.)

We spoke with Fulfil CEO Mir Aamir about what makes the company’s technology stand apart, and how it could reduce food waste by as much as 800 million pounds a year while improving retailers’ profits and lowering shoppers’ costs.

DCVC: What’s the basic idea behind Fulfil? What’s the overarching problem you’re trying to address?

Aamir: Online grocery shopping took off during the pandemic and has continued to grow, with annual sales expected to double to $200 billion in the U.S. alone by 2027. However, there are a few big problems with the current business model. One is that the cost to manually fulfill online grocery orders results in a loss — even before delivery costs are factored in. As a result, online grocery is very expensive for customers, pick-up can be inconvenient, and product substitutions occur frequently.

Fulfil is trying to solve all of these problems and more with a fully automated robotic system for online grocery order fulfillment that’s profitable per order, out the door, for grocers, and lower cost for consumers, at the same time. To deliver this economics breakthrough, our differentiated robotics platform leverages AI, machine learning, and optical and sensor technologies to enable next-generation inventory management and quality control. Our proprietary dispense stations handle any grocery item with computer-vision precision, and sensor fusion algorithms confirm that every item is packed successfully. Inside our warehouses is a fleet of autonomous “shop bots” that split and sequence items to prevent damage and minimize pack time, while dispense stations redistribute inventory to balance load. A database tracks every item’s location, origin, and expiration for a new level of real-time inventory management that enables perfect order accuracy and minimizes waste.

DCVC: You mentioned that your technology keeps track of every single unit individually — for example, each and every tomato. How could this feature help reduce the problem of food waste in the retail sector, and are there other benefits?

Aamir: Fulfil’s ability to track each item gives stores highly accurate visibility into the quantity, quality, and life of products. This data is automatically fed into AI-powered inventory models, which in turn can also predict which food items will need to be discounted in order to move them as they approach expiration. This practice, known as dynamic pricing, is by no means new — you see it when you book flights or hotel rooms, for example. Some supermarkets use approximate dynamic pricing to move items like baked goods or meats before they go bad, but until now it hasn’t been applied scientifically, precisely, and at scale.

Researchers have used economic models to show that if grocery retailers used dynamic pricing to progressively lower prices for perishable foods, it would dramatically curb food waste. A recent study from the University of California San Diego’s Rady School of Management found that dynamic pricing not only cuts the amount of waste by about a fifth, but also increases retailers’ gross margins by about 3 percent.

If you consider that US retail stores generate about 16 billion pounds of food waste every year and Fulfil has the potential to automate 5 percent of U.S. grocery shopping, then it stands to reason that our system could reduce annual food waste in this country by around 800 million pounds.

It’s worth mentioning one additional benefit: the dynamic pricing allowed by our system can make perfectly edible and nutritious perishable items like fresh produce, dairy, and meats affordable to so many consumers who cannot afford them at regular prices. This is incredibly important in the current economic environment of persistently high inflation, which eats into consumers’ grocery budgets. We believe that delivering lower costs for healthier food, and helping end “food deserts,” is big win for society — and one that grocers made profitable by our platform would be happy to support.

DCVC: What’s Fulfil’s roadmap for getting your platform deployed at scale, so that it can take a meaningful bite out of the problem of food waste at the retail level?

Aamir: Our first automated micro-fulfillment center is up and running in Mountain View, California, where our technology is powering a same-day grocery delivery and pick-up service called Lucky Now, in partnership with The Save Mart Companies and DoorDash. Because our automated platform can be customized to meet the needs of grocery stores of any size anywhere in the world, we’re seeing significant traction from retailers globally. We expect to deploy our automation system with several retailers next year and beyond.